Global Autonomous Machines for Batch-Size-One Manufacturing Market 2026–2036: Growth Driven by Flexible Automation

Autonomous machines for batch-size-one manufacturing expected to reach USD 4.2 Billion by 2036, growing at 8.8% CAGR.

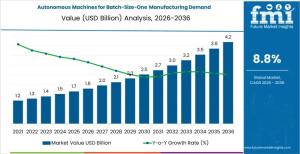

NEWARK, DE, UNITED STATES, January 20, 2026 /EINPresswire.com/ -- The Autonomous Machines for Batch-Size-One Manufacturing Market is entering a high-growth phase as manufacturers seek to produce highly customized products efficiently while reducing setup costs and improving responsiveness. The market is projected to expand from USD 1.8 billion in 2026 to USD 4.2 billion by 2036, reflecting a strong CAGR of 8.8%. Growth is increasingly shaped by value creation across flexible automation, adaptive software, and modular hardware systems rather than simple equipment shipments.

Suppliers that combine reconfigurable machining centers with proprietary adaptive control software, digital twin simulations, and skilled technician training are capturing higher margins. Buyers are placing greater emphasis on precision, traceability, and rapid changeover capabilities, allowing vendors with validated performance to maintain pricing discipline and long-term customer relationships.

Request For Sample Report | Customize Report | Purchase Full Report –

https://www.futuremarketinsights.com/reports/sample/rep-gb-31516

Key Market Metrics at a Glance

• Market Value (2026): USD 1.8 Billion

• Forecast Value (2036): USD 4.2 Billion

• Forecast CAGR (2026–2036): 8.8%

• Leading Technology Type: Reconfigurable Machining Centers

• Fastest-Growing Applications: Custom Electronics Assembly, Personalized Medical Devices, Bespoke Automotive Components

• High-Growth Regions: South Korea, Germany, China, USA, Japan

Why the Autonomous Machines Market Is Growing

The market is expanding steadily due to rising demand for economically viable production of single-unit products across electronics, medical devices, automotive, and luxury goods. Enterprises are investing in flexible automation to reduce traditional setup times, ensure precise quality, and maintain production traceability. Technological advancements are accelerating adoption, including:

Reconfigurable machining centers that automatically adjust tooling and fixtures for each unique unit

• Adaptive manufacturing software enabling real-time process adjustments based on product specifications

• Modular hardware and material handling platforms to accommodate varying geometries and production requirements

• Digital twin integration to simulate and validate each manufacturing process before physical production

These developments are expanding use cases across custom electronics, personalized medical devices, bespoke automotive components, prototype production, and high-value luxury goods.

Segment Insights: Technology and Application Trends

Reconfigurable Machining Centers Drive Market Share

Reconfigurable machining centers account for approximately 42% of the market, favored for their ability to perform rapid automated changeovers without manual intervention. Adaptive assembly systems hold around 28%, supporting automated placement and joining of components with varying specifications. Flexible material handling platforms represent 18%, while modular additive manufacturing systems contribute 8%, and other flexible manufacturing technologies account for 4%.

Custom Electronics and Medical Devices Lead Applications

Applications with the highest growth potential include custom electronics assembly (38%), personalized medical devices (24%), and bespoke automotive components (20%). Prototype and small-series production (12%) and jewelry/luxury goods (6%) are emerging niches, reflecting the increasing need for individual unit customization.

Regional Growth Outlook

- South Korea: Leads with a 9.6% CAGR, driven by consumer electronics customization and semiconductor manufacturing

- Germany: Expands at 9.2% CAGR, supported by custom automotive production and Industry 4.0 integration

- China: Grows at 8.9% CAGR as domestic and export-driven manufacturers adopt flexible automation

- USA: Records 8.4% CAGR with aerospace, medical device, and prototype-focused adoption

- Japan: Advances at 7.8% CAGR, emphasizing precision manufacturing and quality consistency

Competitive Landscape: Technology-Driven Differentiation

Competition is increasingly defined by the integration of hardware, software, and service offerings. Leading players include DMG MORI Co., Ltd., TRUMPF SE + Co. KG, Mazak Corporation, Haas Automation, Inc., and Okuma Corporation. Automation and software providers such as Siemens, Rockwell Automation, and Schneider Electric support adaptive manufacturing operations, while robotics companies including KUKA, ABB, and FANUC supply modular systems for assembly and material handling. System integrators and research institutions contribute to standardization, adaptive algorithm development, and best practices for efficient single-unit production.

Market Challenges and Adoption Constraints

Despite strong growth prospects, adoption is moderated by high upfront system costs, operator training requirements, and integration with existing production lines. Enterprises must invest in digital twins, process validation, and quality verification systems to ensure economic viability for single-unit production. Skilled technicians are essential to manage complex flexible automation systems, and incremental pilot deployments remain a critical strategy for risk mitigation.

Related Reports:

Air Compressor Pressure Switch Market- https://www.futuremarketinsights.com/reports/air-compressor-pressure-switch-market

AI Recognition Machine Vision Alignment Systems Market- https://www.futuremarketinsights.com/reports/ai-recognition-machine-vision-alignment-systems-market

Pre-engineered Buildings Market- https://www.futuremarketinsights.com/reports/pre-engineered-buildings-market

Have a specific Requirements and Need Assistant on Report Pricing or Limited Budget please contact us - sales@futuremarketinsights.com

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Contact Us:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

Why FMI: https://www.futuremarketinsights.com/why-fmi

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

Sudip Saha

Future Market Insights Inc.

+1 347-918-3531

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.